The Rock Island Arsenal Surface Finishing Plant

ITI provided design-build services for multi-phase renovation and modernization of the Rock Island Arsenal (RIA) Joint Manufacturing & Technology Center (JMTC), Building 212 Surface Finishing Plant, in Rock Island, IL, under an Energy Savings Performance Contract (ESPC). The project required development of a master plan for phased demolition and construction of a new plant with no lost production. The project resulted in reduction of ventilation from 500,000 cfm to <40,000 cfm while also adding new processing capabilities. The savings were realized by (1) right sizing and vertical orientation of equipment; (2) integration of an innovative ventilation system, which included automated tank covers and ventilation dampers with priority-based constraints that limit the number of covers that could be opened concurrently; and (3) automated management of equipment operating modes (Inactive, Standby, and Active) to reduce ventilation requirements and energy usage.

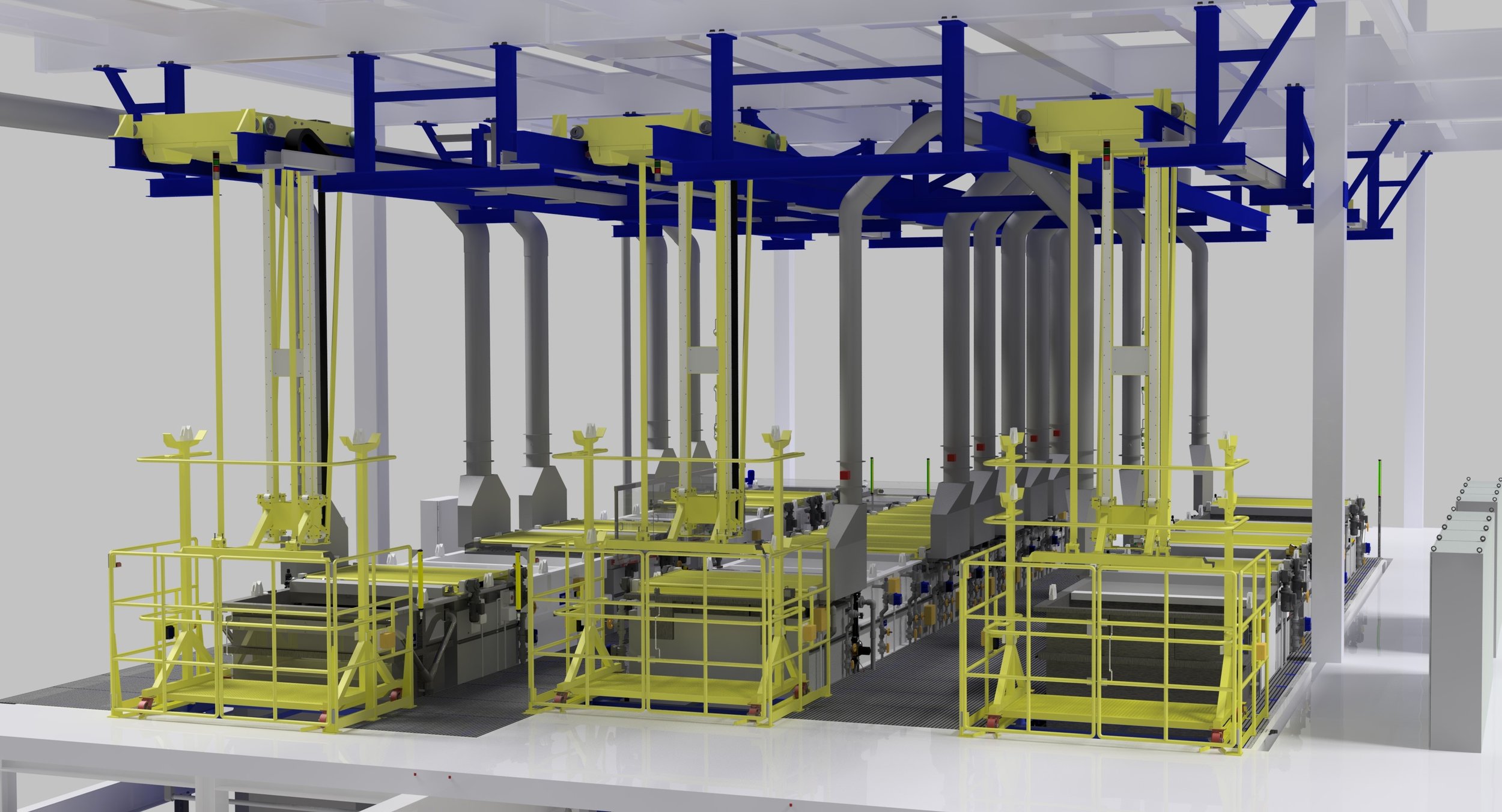

ITI’s work scope included project planning, engineering and design, equipment fabrication and FAT, installation, functional and process commissioning, and training. The manufacturing capabilities of the JMTC include a plating department, which applies surface finishes to its products. This area can process components from the very small to up to 20 feet in length. Surface finishing process capabilities now include cadmium, chromium, copper, nickel, lead alloy, and zinc electroplating; Type I, II, and III anodizing; light and heavy zinc and manganese phosphate coatings; black oxide; conversion coating for aluminum, cadmium, and zinc substrates; titanium and aluminum etching; and stainless-steel descaling and passivation.