The NORDAM Group Facility

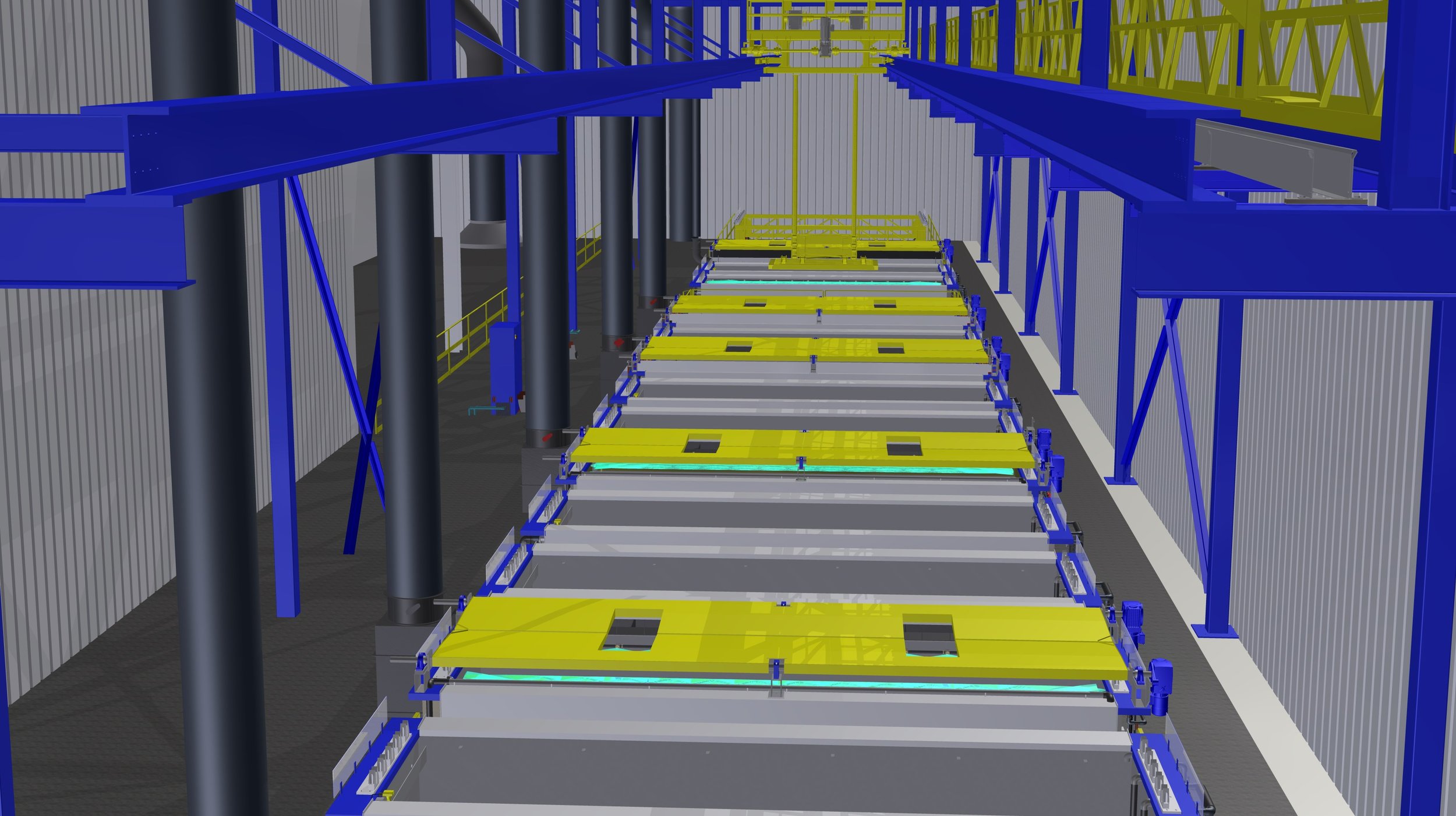

ITI provided engineering design services, equipment fabrication, installation, commissioning, and training for a new Phosphoric Acid Anodizing and FPL Etch Process Line at NORDAM’s facility located in Tulsa, OK. ITI designed and built this new, fully-automated, and continuously operating line in a new building area that was specifically constructed with ITI design support for this project. This wet process line is integrated with a power & free conveyor system feeding paint and curing operations with automatic transfer between systems. This new line enables NORDAM to process aluminum sheets, with an individual load weight up to 1500 pounds per flight bar, with the capacity to simultaneously process up to five flight bars.